3D Printing: Transforming Industries in the New Industrial Revolution

Did you know that 3D printing could boost the global economy by $1 trillion by 2025? This technology is at the forefront of the new industrial revolution, transforming how businesses operate. Companies are leveraging 3D printing to create customized products faster and cheaper than ever before. It’s not just about prototyping anymore; it’s about real profits and art.

Embracing this innovation opens doors to endless possibilities in manufacturing, design, art, and even healthcare. From reducing waste to speeding up production times, 3D printing is changing the game. Businesses that adapt will thrive, while those that don’t may fall behind. Discover how you can profit from this groundbreaking technology and stay ahead in a rapidly evolving market.

Key Takeaways

- Understand how 3D printing is changing industries by learning its key roles and benefits to stay competitive.

- Explore various applications of 3D printing, from healthcare to automotive, to identify opportunities for innovation in your business.

- Keep an eye on future trends in 3D printing technology to adapt and position your business for growth.

- Implement strategies discussed in the article, like investing in training and partnerships, to maximize profits from 3D printing.

- Utilize 3D solutions to enhance efficiency in your operations, reducing waste and improving production speed.

- Leverage customization options offered by 3D printing to meet customer needs and stand out in the market.

Understanding 3D Printing’s Role in Industry

Definition of 3D Printing

3D printing, also known as additive manufacturing, creates three-dimensional objects from digital files. This technology builds items layer by layer. It uses materials like plastic, metal, and resin. The significance of 3D printing lies in its ability to transform how products are made. It allows for faster prototyping and reduces waste compared to traditional methods.

Transition to Large-Scale Production

Initially, 3D printing focused on creating prototypes. Designers used it to test concepts quickly. Over time, the technology evolved. Now, it supports large-scale production in various industries. For example, companies can produce thousands of parts using 3D printers. This shift enables businesses to respond faster to market demands.

Impact on Traditional Manufacturing

3D printing disrupts traditional manufacturing methods significantly. Conventional processes often require molds and extensive machinery. These methods can be costly and time-consuming. In contrast, 3D printing reduces these needs. It lowers production costs and shortens lead times. Industries now enjoy greater flexibility in design.

For instance, the automotive industry benefits greatly from this technology. Manufacturers can create complex components that were impossible with traditional methods. Aerospace companies also use 3D printing for lightweight parts, improving fuel efficiency.

The design industry sees a similar impact. Designers can experiment with intricate shapes without worrying about production constraints. This freedom fosters innovation and creativity.

Advantages of 3D Printing

- Cost Efficiency: Reduces material waste.

- Customization: Allows unique designs for specific needs.

- Speed: Accelerates the production process.

- Accessibility: Makes manufacturing possible for small businesses.

Challenges in Adoption

Despite its advantages, challenges exist in adopting 3D printing across industries:

- Quality Control: Ensuring consistent quality can be difficult.

- Material Limitations: Not all materials are suitable for 3D printing.

- Regulatory Issues: Compliance with industry standards is necessary.

Exploring Diverse Applications of 3D Printing

Healthcare Innovations

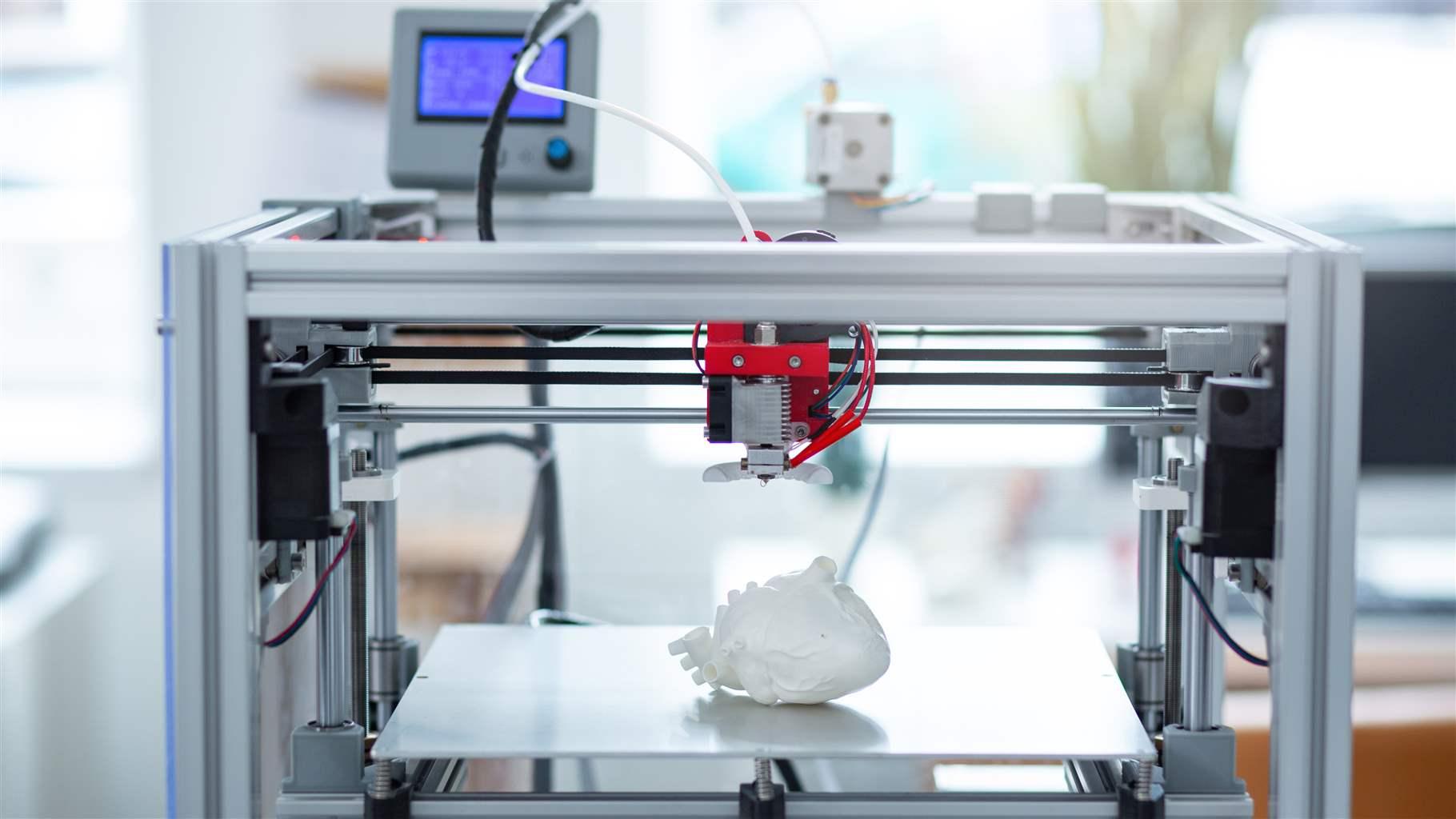

Healthcare is one of the leading industries using 3D printing technology. Hospitals create custom implants and prosthetics tailored to individual patients. This process allows for better fits and improved comfort. In 2018, researchers at the University of Utah printed a heart model for surgical planning. Such applications show how 3D printing designs can enhance patient care.

Companies like Organovo focus on bioprinting tissues for drug testing. They aim to reduce reliance on animal testing. Their work highlights the potential for creating human tissues that mimic real organs. This innovation could change how medical research is conducted.

Packaging Solutions

The packaging industry also benefits from 3D printing products. Companies use this technology to create prototypes quickly. Traditional methods often take weeks, but 3D printing can cut this time down to days. For example, Coca-Cola has explored using 3D printers to design new bottle shapes.

These quick iterations help businesses adapt to market demands faster. Custom packaging solutions are possible with personal 3D printers. Brands can test various designs before mass production, saving time and resources.

Art and Design

Artists embrace 3D printing technology for unique creations. Artists can design complex structures that would be difficult to make by hand. For instance, artist Anouk Wipprecht uses 3D printers to create wearable art pieces. These pieces blend fashion with technology.

Universities also play a role in advancing art through 3D printing. Many institutions offer courses on digital fabrication techniques. Students learn how to combine traditional artistic skills with modern technology.

Prototyping and Testing

Prototyping remains a core function of 3D printing across various sectors. Engineers use it for rapid prototyping of new products. This method allows them to test designs before full-scale production begins. Companies like Tesla utilize consumer 3D printers for developing parts efficiently.

Testing prototypes helps identify flaws early in the design process. This approach saves money and reduces waste in manufacturing. It encourages innovation by allowing teams to experiment without significant costs.

Customized Solutions

Customization is another significant advantage of 3D printing. Businesses can produce items tailored specifically to customer needs. For example, Nike offers personalized shoe designs using 3D printing methods. Customers can choose colors, materials, and even fit preferences.

This trend toward customization extends beyond consumer goods. Industries such as aerospace and automotive also leverage this technology for bespoke components. Each sector finds unique ways to utilize 3D printing for their specific requirements.

Future Prospects of 3D Printing Technology

Emerging Trends

3D printing technology is evolving rapidly. New technologies are emerging every year. These advancements improve speed, quality, and cost-efficiency. For example, art 3D printing technology has gained popularity in creative fields. Artists use it to create intricate designs that were once impossible to produce.

In the medical field, innovations are transforming patient care. 3D printing allows for customized prosthetics. Patients can receive prosthetic options tailored to their specific needs. This personalization enhances comfort and functionality.

Potential Breakthroughs

Several potential breakthroughs could reshape industries. One area is construction. 3D printing can create entire structures with less waste and lower costs. In 2021, a company built a house in just 24 hours using this method.

Another promising area is bioprinting. Scientists aim to print human tissues and organs. This advancement could revolutionize transplant medicine. It may reduce the need for donors and waiting lists.

The automotive industry also sees benefits from 3D printing. Manufacturers use it to produce lighter parts, improving fuel efficiency. Companies like BMW have already integrated these techniques into their production lines.

Collaboration Importance

Collaboration between educational institutions and businesses is crucial for advancing 3D printing technology. Schools teach students about new technologies. They prepare them for careers in this growing field.

Partnerships allow businesses to access fresh ideas from students. Universities benefit from real-world challenges presented by companies. This teamwork fosters innovation and accelerates development.

Programs focusing on hands-on experience are essential. Internships provide students with practical skills. They learn how to operate printers and design models.

Real-World Applications

Real-world applications of 3D printing are expanding daily. The fashion industry uses it to create unique clothing items. Designers experiment with new materials that traditional methods cannot achieve.

Food production also explores this technology. Chefs print edible ingredients, creating customized meals. This trend could change how we think about cooking and dining.

In aerospace, companies utilize 3D printing for lightweight components. NASA even tests printed parts for rockets and satellites.

Transforming Manufacturing Processes with 3D Printing

Streamlined Production Workflows

3D printing processes simplify production workflows significantly. Traditional manufacturing technologies often require multiple steps and machinery. In contrast, additive manufacturing allows for creating complex parts in one go. This reduces the need for assembly lines and minimizes handling time.

Manufacturers can now produce items directly from digital files. This shift leads to a more efficient process. With industrial 3D printers, companies can quickly switch between designs without major downtime. This adaptability allows businesses to respond faster to market demands.

Waste Reduction

3D printing equipment contributes to less waste in production. Traditional methods often cut away excess material, leading to scraps. On the other hand, additive manufacturing builds objects layer by layer. This technique uses only the necessary material, which cuts down on waste.

For instance, in the manufacturing industry, metal 3D printing produces components with minimal leftover material. Companies that adopt this approach not only save resources but also lower costs. The reduction of resource consumption benefits both manufacturers and the environment.

Speed of Prototyping

Rapid prototyping is another advantage of 3D printing technology. Designers can create prototypes in days rather than weeks or months. This speed accelerates product development cycles significantly.

With smart manufacturing techniques, teams can test ideas quickly. They can make adjustments based on feedback within a short period. This quick turnaround helps companies stay competitive. For example, medical products benefit greatly from rapid prototyping. Medical device developers can test and refine their designs swiftly, improving patient care.

Adaptable Manufacturing Processes

Adaptable manufacturing processes are crucial in today’s fast-paced market. 3D printing allows manufacturers to customize products easily. They can adjust designs based on customer needs without extensive retooling.

This flexibility leads to personalized solutions in various sectors, including packaging and consumer goods. Manufacturers can create smaller batches tailored to specific requests, enhancing customer satisfaction.

Strategies to Profit from 3D Printing

Integration Techniques

Businesses should explore various strategies to integrate 3D printing into their operations. Start by assessing current manufacturing processes. Identify areas where 3D printing can reduce costs and improve efficiency. This may include prototyping or producing small batches of products.

Adopting a hybrid model can also be beneficial. Combine traditional manufacturing with 3D printing. This allows companies to maintain production speed while enjoying the flexibility of additive manufacturing. For example, automotive companies often use 3D printing for custom parts while relying on traditional methods for mass production.

Customized Products

Market opportunities abound for businesses that offer customized products and services. Consumers increasingly demand personalization in their purchases. Companies can leverage 3D printing to create tailored items that meet specific customer needs.

For instance, businesses can produce custom jewelry or personalized gifts. They can also create bespoke medical devices, like prosthetics designed for individual patients. The ability to produce unique items gives companies a competitive edge.

Investment in Training

Investing in training is crucial for maximizing the benefits of 3D printing technology. Employees must understand how to operate and maintain 3D printers effectively. Providing hands-on training sessions can enhance skills and confidence.

Staying updated on the latest advancements in 3D printing is essential. Encourage staff to participate in workshops or online courses. Knowledgeable employees can drive innovation within the company.

Cost Management

Cost management plays a key role in successfully profiting from 3D printing. Businesses must evaluate the expenses associated with materials and equipment. Selecting the right materials can lead to significant savings over time.

Consider using recycled or biodegradable materials when possible. This not only reduces costs but also promotes sustainability. Companies that prioritize eco-friendly practices often attract environmentally conscious consumers.

Partnerships and Collaborations

Forming partnerships with other organizations can enhance capabilities in 3D printing. Collaborating with tech firms or research institutions can provide access to advanced resources and expertise. These partnerships may lead to innovative product development and shared knowledge.

Networking with industry peers can also open doors for new opportunities. Attending trade shows or conferences focused on 3D printing allows businesses to learn from others’ experiences.

Continuous Improvement

Finally, businesses should adopt a mindset of continuous improvement regarding their 3D printing strategies. Regularly assess performance metrics to identify areas for enhancement. Gathering feedback from customers helps refine product offerings.

Implementing changes based on data analysis ensures that companies stay competitive in the evolving market landscape.

Enhancing Business Efficiency with 3D Solutions

Supply Chain Optimization

3D printing revolutionizes supply chain management. Companies can produce tangible products on demand. This reduces the need for large inventories. Businesses save money by minimizing storage costs. Engineers can design and print parts directly from digital files. This cuts down on transportation times and costs.

With 3D solutions, companies can respond to market changes faster. They can adjust production based on customer needs. This flexibility leads to improved customer satisfaction. For example, a company producing custom parts can quickly adapt to specific orders. This agility is essential in today’s fast-paced market.

Reduced Lead Times

3D printing significantly lowers lead times for product development. Traditional manufacturing often requires long setup times and multiple processes. In contrast, 3D printing allows for rapid prototyping. Companies can create a prototype in hours instead of weeks.

This speed enhances innovation within businesses. Teams can test new ideas quickly. They gather feedback and make adjustments without wasting resources. As a result, companies launch products faster than before. This quick turnaround gives them a competitive edge.

Increased Productivity

Automation plays a crucial role in maximizing productivity through 3D printing. Digital workflows streamline the entire production process. By integrating software, companies reduce manual tasks and errors.

Engineers use 3D printers to automate repetitive tasks. This frees up time for more complex projects. Employees focus on creative problem-solving rather than mundane work. The result is a more engaged workforce that drives business growth.

Furthermore, 3D printing technology enables large-scale production with fewer resources. It minimizes waste by using only the necessary materials for each project. Companies benefit from lower production costs while maintaining quality.

Meeting Customer Needs

3D printing also allows businesses to meet specific customer needs effectively. Customization is easier than ever before. Companies can produce unique items tailored to individual preferences.

For instance, a company might offer personalized gifts or specialized tools for clients. Such innovations enhance customer loyalty and drive sales growth.

In summary, 3D solutions provide numerous benefits for businesses today. They optimize supply chains, reduce lead times, and increase productivity through automation. Companies that embrace this technology position themselves for future success.

Customization and Personalization Benefits

Market Demand

The demand for personalized products has surged in recent years. Consumers now expect items tailored to their specific needs. This trend spans various markets, from fashion to healthcare. In 2021, a survey showed that 70% of consumers favored brands that offered customization options. This shift reflects a broader desire for unique solutions.

Businesses must adapt to this changing landscape. They need to understand customer preferences and offer personalized experiences. The rise of e-commerce has further fueled this demand. Online shoppers seek products that match their styles and requirements.

Tailored Solutions

3D printing technology plays a crucial role in meeting these demands. It allows companies to create customized designs quickly and efficiently. This technology enables businesses to produce items on demand. Customers can receive products made just for them without long wait times.

For example, in the healthcare field, 3D printing makes it possible to design prosthetics tailored to individual patients. Traditional methods often take weeks or months. With 3D printing, it can take only days. This rapid turnaround improves patient satisfaction and outcomes.

Another area benefiting from 3D printing is the fashion industry. Designers use this technology to create one-of-a-kind pieces. They can experiment with materials and shapes that were previously impossible or too costly to produce. This flexibility allows for greater creativity and innovation.

Success Stories

Many businesses have successfully leveraged customization through 3D printing technology. For instance, Nike introduced the “Nike By You” program in 2019. Customers can personalize their shoes with different colors and materials. This approach has increased customer engagement and sales.

Another example is the company Formlabs, which specializes in 3D printing solutions for dental practices. They provide custom dental aligners based on individual patient scans. This service reduces treatment time and enhances patient comfort.

Local businesses also benefit from this technology. A small jewelry maker used 3D printing to create unique pieces based on customer designs. This strategy not only attracted new clients but also built a loyal customer base.

Cost-Effectiveness and Economic Impact

Efficiency

3D printing offers significant efficiency in production. Traditional manufacturing often involves multiple steps and processes. These can take time and resources. In contrast, 3D printing creates parts directly from digital files. This reduces the need for assembly lines and additional labor. Companies can produce items faster and with less effort.

Cost savings are notable. Studies show that 3D printing can lower production costs by up to 70%. Materials used in 3D printing are often cheaper as well. Waste is minimized since printers only use the necessary amount of material. Traditional methods can leave behind a lot of scrap material. Reducing waste not only saves money but also benefits the environment.

Market

The market for 3D printing technology is expanding rapidly. As businesses recognize its advantages, they adopt it more widely. The global 3D printing market was valued at approximately $13 billion in 2020. It is expected to reach around $63 billion by 2026, according to industry reports.

This growth indicates a shift in how products are made. Industries such as healthcare, automotive, and aerospace are leading this change. For example, hospitals use 3D printing for prosthetics and surgical tools. This allows for customized solutions tailored to individual patients. Similarly, car manufacturers create prototypes quickly, reducing time to market.

Waste

Reducing waste is another critical factor in the economic impact of 3D printing. Traditional manufacturing often results in excess materials that go unused. This contributes to higher costs and environmental issues. With 3D printing, materials are added layer by layer. Only the needed amount is used, which significantly cuts down on waste.

Companies looking to be more sustainable find this appealing. They can improve their public image while saving money. Sustainable practices become part of their business model, attracting eco-conscious consumers.

Job Creation

The rise of 3D printing also leads to job creation and new business models. As companies invest in this technology, they require skilled workers who understand it. This includes engineers, designers, and technicians trained in additive manufacturing techniques.

New startups emerge focused on 3D printing services and products. Entrepreneurs see opportunities in niches like custom designs or rapid prototyping. These ventures contribute to local economies and create jobs in various sectors.

Closing Thoughts

3D printing is reshaping the industrial landscape. Its ability to enhance efficiency, reduce costs, and offer customization opens doors for businesses like yours. The technology isn’t just a trend; it’s a revolution that can elevate your operations and boost profits.

Now’s the time to dive in. Explore how 3D printing can transform your business strategy. Embrace this innovation to stay ahead of the competition and maximize your potential. Don’t wait—start leveraging 3D printing today for a profitable tomorrow.

Frequently Asked Questions

What is 3D printing technology?

3D printing technology, also known as additive manufacturing, creates three-dimensional objects by layering materials based on digital models. It’s revolutionizing industries by enabling rapid prototyping and complex designs.

How does 3D printing benefit manufacturing?

3D printing streamlines manufacturing processes by reducing waste, lowering production costs, and allowing for quick iterations. It enhances flexibility and speeds up the time from concept to market.

What industries are utilizing 3D printing?

Industries ranging from aerospace and automotive to healthcare and fashion are leveraging 3D printing. Its versatility supports diverse applications, including prototyping, tooling, and end-use parts.

Can 3D printing reduce costs?

Yes, 3D printing can significantly reduce costs by minimizing material waste and lowering labor expenses. It also allows for on-demand production, eliminating excess inventory.

How does customization work with 3D printing?

3D printing enables high levels of customization. Businesses can create tailor-made products that meet specific customer needs without the constraints of traditional manufacturing methods.

What are the future prospects of 3D printing?

The future of 3D printing looks promising with advancements in materials and technology. Expect increased adoption across industries, enhanced capabilities, and integration with automation and AI.

How can businesses profit from 3D printing?

Businesses can profit by adopting 3D printing to improve efficiency, reduce costs, and offer customized solutions. Embracing this technology positions companies competitively in the evolving market landscape.

Send Buck a voice message!

Send Buck a voice message!